Welding defects can be said to be the irregularities formed in a given weld metal as a result of incorrect welding patterns, wrong welding process, or due to poor welding skills from the welder's part. Weld flaws may come in different sizes, shapes, and degrees of severity.

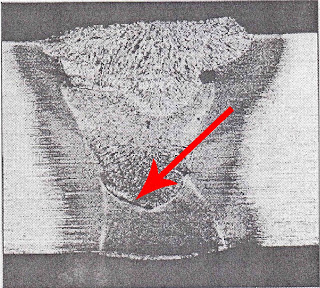

Commmon Joint and Weld Types. Arc welding is taking two or more separate pieces of metal. Lack Of Inter Run Fusion. Cacat Las yang tidak fusi di antar layer atau pass weld metal, cacat ini terjadi dapat dikarenakan arus yang terlalu rendah, sudut elektroda yang tidak tepat dan pengelasan terlalu cepat. LACK OF FUSION Lack of fusion, also called cold lapping or cold shuts, occurs when there is no fusion between the weld metal and the surfaces of the base plate. This defect can be seen in Figure 10-2. The most common cause of lack of fusion is a poor welding technique. 'Fusion or lack of differentiation is where individual choices are set aside in service of achieving harmony in the system' (Brown, 1999). 2 ways to abbreviate Lack Of Fusion. How to abbreviate Lack Of Fusion? Get the most popular abbreviation for Lack Of Fusion updated in 2020.

There are different types of welding defects that can transpire during the welding process. From porosity and cracking, to burn through and undercut, each has several causes.

However, regardless of the application and material on which they occur, one thing remains true to all of them; they're common, costly, cause downtime and loss of productivity.

Luckily enough, there are various remedies that can help welders minimize these welding defects. In this article, we shall be discussing the seven most common welding defects, causes, and remedies plus 2 others.

Keep reading!

What are welding defects?

Welding defects/flaws can be defined as weld surface irregularities, imperfections, discontinuities, or inconsistencies that are formed in welded parts.

These defects differ from the desired weld bead size, shape, and quality. Welding defects could occur either from the outside or inside the weld metal.

Defects in weld joints could cause the rejection of parts and assemblies, an increase in the cost of maintenance, a reduction in performance and could cause catastrophic failures posing the risks of loss of life and property.

Welding defects and remedies

Mistakes sometimes occurs during a welding process. These could lead to different forms of welding defects. As a guide, We present to you the seven most common welding defects and their preventive measures.

1. Porosity

Porosity usually occurs as a result of weld contamination. This happens when gas is trapped inside or along the surface of the weld metal. Just like other weld defects, Porosity results in weak welds that may easily collapse.

• Causes of Porosity:

Often, Contaminated or inadequate shielding gas is the common cause of porosity.

However, Porosity could also be caused by using too high gas flow, longer arc, inadequate electrode deoxidant, and the presence of paint, rust, grease, or oil.

At the same time, having a dirty base metal or extending the welding far beyond the nozzle could cause porosity.

Additionally, air currents from cooling fans may contaminate the shielding gas envelope around the weld-puddle, thereby causing porosity.

Another common cause of this welding flaw is poor seal (loose-fitting) in the shielding gas channel.

• Remedies for Porosity:

You can remedy the porosity of a weld by; cleaning the materials to be welded before you begin welding, using correct arc distance, employing the proper welding technique, and using the right electrodes.

Again, ensure that there is adequate gas flow and replace any gas hoses that may be causing leaks. Also, when welding outside or in drafty areas, place a welding screen around the work area. This will help ameliorate porosity issues.

2. Undercutting

Undercutting is a crater or groove that is formed near the toe of the weld. In this case, the weld metal fails to fill-in the grooved area resulting in a weak-weld that is liable to cracking along the toes.

• Causes of Undercutting:

Wrong filler metal, excessive heat, fast weld speed, as well as poor welding technique, may all leads to undercut welding defect on a welding joint.

Also, very high weld current, incorrect use of shielding gas and using the wrong electrode could cause undercuts.

• Remedies for Undercutting:

Undercutting in welding can be avoided by employing the right welding technique that does not involve excessive weaving.

Lowering the arc length and minimizing the travel speed of the electrode can also help prevent undercutting.

Another remedy to undercutting problem is adjusting the angle of the gun to point directly towards the weld joint.

3. Burn Through

As the name implies, burn through occurs when the weld metal penetrates through the base metal, burning through it. This kind of welding flaw is most common with soft or thin metals, especially those that are 1/4″ or less. Also too much weld penetration can often lead to burn through.

• Causes of burn through:

The primary cause of burn through is excessive heat. Also having too large root opening on the weld joint can results in burn through.

• Remedies for burn through:

When burn through occurs, the easiest way to rectify the problem is to lower the voltage and the wire feed speed.

Also increasing the travel pace can help remedy the problem, especially when welding on aluminum material.

Increasing the wire extension and using a weaving technique while welding can also help minimize the potential for burn through.

4. Incomplete Penetration

Incomplete joint penetration (lack of penetration) happens when there is a shallow fusion between the base metal and filler metal, rather than full penetration of the joint. It results in a gap, cracks, or even joint failure.

• Causes of incomplete joint penetration:

Incomplete joint penetration could occur when the groove you are welding is too narrow, and the weld metal does not reach the bottom of the joint.

Improper joint preparation and insufficient heat input are the two primary causes of lack of penetration. Improper shielding gas mixture and welding wire diameter can also be a factor.

Also, if you leave too much space between the two metals you are welding, the metals will not melt together on the first pass and hence results in incomplete penetration.

• Remedies for incomplete penetration:

There are a number of remedies for incomplete joint penetration; this includes; using higher wire feed speed and voltage, reducing the travel pace to allow more weld metal penetrates through the joint, and proper joint design and preparation.

The joint should be prepared in such a way to allow the welder to maintain the proper wire extension and still access the bottom of the weld joint. Again, ensure that ‘the wire type and diameters' and ‘the gas and the gas mixture' are compatible.

5. Cracks

Weld Cracks are the most serious type of welding defects. Weld Cracks are not acceptable in the welding industry.

However, a crack may occur just about everywhere in a weld; in the weld metal, on the plate next to the weld metal, or anyplace affected by intense heat.

The three major types of weld cracks are: Hot cracks, cold cracks, and crater cracks

• Causes of weld cracks:

Weld Crack could be caused by so many things such as base metal contamination, poor joint design, failure to preheat before welding, low welding current, high welding speed, using hydrogen when welding ferrous materials and welding at too high voltage.

• Remedies for weld cracks:

You can prevent this type of weld flaw by using the right metal. Proper joint design and preparation is also another way to prevent cracking. Crater cracking can be prevented by using a backfilling technique. Right Selection of filler metal and shielding gas can also help prevent cracking problems.

6. Incomplete Fusion

Incomplete fusion occurs when the weld metal fails to properly fuse with the base metal, or when the individual weld beads don't fuse together. This type of weld defect is also referred to as cold lap.

• Causes of incomplete fusion

Incorrect gun angle is the most common cause of incomplete fusion. However, contaminants on the base metal and insufficient heat can also cause this weld defect.

In some instances, too short arc length, very high travel speed, too low welding amperage or when the electrode size is too small for the thickness of the metal you are welding, all could result to incomplete fusion.

• Remedies for incomplete fusion:

The very first thing to do to prevent this weld flaw is to properly clean the base metal before you start the welding; make sure that the base metal is free of oil, grease, dirt or other debris.

Make sure the weld angle is between 0 to 15 degrees; this will allow you to fully access the groove of the weld.

Also, for joints that require weaving technique, holding the arc on the sidewall for some time is very vital to help prevent this type of defect. Ensure that there is enough heat input to coalesce the base metal and the weld metal fully.

7. Slag Inclusions

Slag is the waste material that is usually formed while welding, bits of this solid waste material may accidentally be incorporated into the weld and causes contamination.

• Causes of slag inclusions:

Some of the common causes of slag inclusions include failure to properly clean a welding pass before applying the next pass, incorrect welding angle, incorporation of flux from stick welding electrode, and too low welding amperage.

8. Warpage

Warpage is an unwanted distortion in the shape of a piece of metal. This occurs when the welder fails to properly control the expansion and contraction of the base material.

• Causes of warpage:

Warpage may arise when the welder clamps the welding joints too tightly, welding a piece of metal over and over again can also cause the metal to warp.

When welding a T-joint, the vertical part of the ‘T' may sometimes pull itself towards the weld. Also, the more heat input you use, the more the chances you have to end up with a warpage.

• Remedies for warpage:

Warpage can be prevented by using only the required amount of heat. Opting for moderate travel speed and wire feed speed while welding can also help curtail the problem of warpage.

9. Overlap

overlap occurs when the weld face extends far above the weld toe. In this case, the weld metal rollout and forms an angle less than 90 degrees.

• Causes of Overlap

Overlap welding defect can arise when using large electrodes greater than the metal size. High welding current and the use of improper welding technique can also cause this defect.

• Remedies for Overlap

Overlap welding defect can be avoided by employing the correct welding Technique, using small Welding electrode and less welding has.

Conclusion

While welding defects and discontinuities may arise due to the welder's poor welding skills, however, even the most skilled and experienced welders may in one way or another experience weld defects.

But the only way to stop these welding irregularities from negatively affecting productivity and increasing the cost of operations is by identifying and rectifying the problems as quickly as possible.

Contents

|

Introduction

There are six different grouping of welding imperfections:

(i) Cracks

(ii) Cavities

(iii) Solid inclusions

(iv) Lack of fusion and penetration

(v) Imperfect shape and dimensions

(vi) Miscellaneous imperfections

Cracks

An imperfection produced by a local rupture in the solid state, which may arise from the effect of cooling or stresses. Cracks are the most critical among the imperfections, as their geometry produces a very large stress concentration at the crack tip, eventually leading to fracture.Types of Cracks (Location)

- Longitudinal crack - can occur in weld metal, HAZ (heat affected zone), or parent metal

- Transverse crack - can occur in weld metal, HAZ (heat affected zone), or parent metal

- Radiating crack - cracks radiating from a common point. It occur in weld metal, HAZ (heat affected zone), or parent metal

- Crater crack - can occur only in in weld metal

- Branching crack - group of connected cracks originating from a common crack. It can occur in weld metal, HAZ (heat affected zone), or parent metal

Types of Cracks (Nature)

Cracks can also be sub-divided based on their nature:

- Hot cracks

- Precipitation induced cracks

- Cold cracks

- Lamellar tearing

Hot cracks

This type of cracking occurs when the weld is starting to solidify, in the pasty state, as it posses very little strength and therefore any residual loading is likely to cause it to break before it has fully solidified. The problem can be compounded by impurities that are forced out of the solidifying weld, becoming trapped in the centre of the weld during final solidification. Hot cracking can occur where their is a high degree of restraint in the structure of the fabrication or where the structure moves slightly as the weld solidifies.

Depending on their location and mode of occurrence, hot cracks can be:

- Solidification crack

- Liquation crack

Solidification crack

It occur as a result of solidification process. It is in weld metal usually along the centerline of the weld. It normally occurs when: weld metal has high carbon or impurity, depth-to-width ratio of the wed bead is large, or when the disruption of the heat flow conditions occurs.The impurities like sulphur and phosphorus are a major factor since these elements segregate during solidification. Hence it is important to remove the oil or grease contamination from the weld area before welding. Also metals like copper, tin, lead, and zinc, with low melting point should be avoided.

These cracks can be wide and open to the surface like shrinkage voids or in sub-surface and narrow.

Solidification cracks are normally readily distinguished from other types of cracks due to the following characteristic factors:

- they occur only in the weld metal

- they normally appear as straight lines along the centreline of the weld bead, as shown above, but may occasionally appear as transverse cracking depending on the solidification structure

- solidification cracks in the final crater may have a branching appearance

- as the cracks are often 'open', they can be visible to the naked eye

Liquation crack

These occurs in the coarse grain HAZ, in the new vicinity of the fusion line as a result of heating the material to an elevated temperature, high enough to produce liquation of the low melting point constituents placed on grain boundaries.

Precipitation induced cracks

These are reheat cracks present in crack resisting steels.

Cold Cracks (Hydrogen induced cracks)

Cold cracks can only occur if all of the following conditions are present:

- Presence of H+ (can be from moisture, organic dirt, oil, grease, paint, etc) - hydrogen level greater than 15 ml/100 g of weld metal deposited

- Susceptible Micro-structure (higher Carbon Equivalent materials are more susceptible) - greater than 400 HV hardness

- Residual Tensile Stresses (present with restrained joints, thick material, no pre-heat, etc) - greater than 0.5 of the yield stress

- Moderate Temperatures (-150 to 100 deg C)

Cold cracking can be prevented thorough the following methodologies:

- Apply preheat to slow down the cooling rate and avoid the formation of susceptible microstructures

- Maintain a specific interpass temperature

- Post head on completion of welding

- Use shielding gas to reduce hydrogen content

- Reduce residual stress

- Clean rust from moisture to prevent formation of hydrogen from water

Lamellar tearing

There is a combination of causes: non-metallic inclusions, too much hydrogen in the material, and shrinkage forces perpendicular to the face of the plates. The main factor among these reasons is the non-metal inclusions, of which the sulfur is the main problem. Lamellar tearing is no longer a problem anymore because sulfur levels are typical kept below 0.005%.

Some things that are done to overcome lamellar tearing are: reducing amount of sulfur in the material or adding alloying elements that control the shape of sulfide inclusions, such as rare earth elements, zirconium, or calcium. A more drastic option is change the workpieces to castings or forgings because this type of defect does not occur in those workpieces.

It is generally recognised that there are three conditions which must be satisfied for lamellar tearing to occur:

- Transverse strain - the shrinkage strains on welding must act in the short direction of the plate ie through the plate thickness

- Weld orientation - the fusion boundary will be roughly parallel to the plane of the inclusions

- Material susceptibility - the plate must have poor ductility in the through-thickness direction

Thus, the risk of lamellar tearing will be greater if the stresses generated on welding act in the through-thickness direction. The risk will also increase the higher the level of weld metal hydrogen

Cavities

Cavity may be either gas cavity due to entrapment of gas or due to shrinkage caused by shrinkage during solidification.The types of cavities that are formed by entrapment of gas are:

- Gas pore

- Worm hole

- Surface pore

Gas pore

Porosity is a condition in which gas pockets or voids occur in a metal as a result of contamination or poor protection of the molten solidifying metal. It is generally accepted that porosity in weld metals is formed by the entrapment of evolved gases in the solidifying weld metal. The discontinuity formed is generally spherical but may be cylindrical.

It has been suggested that bubbles are first formed at the solid liquid interface and remain there until they have grown to a sufficient size to float up through the molten weld metal and escape to the atmosphere.

If the rate of detachment and flotation is less than the rate of advance of the solidification front, the bubbles ate trapped and the resultant weld is porous. In carbon steel welds porosity can result from the following reactions that occur either singly or in combination.

Hydrogen, oxygen and nitrogen are gases dissolved in the metal. Pores in weld metal are, in general, spherical in shape, but pores of other shapes can occur weld metal porosity (black) and heat affected zone (dark portion around the weld bead).

A gas cavity of essentially spherical shape trapped within the weld metal. It can be of various forms:

- Isolated

- Uniformly scattered porosity - is porosity uniformly distributed throughout a single pass weld or through several passes of multiple pass weld. It is usually faulty welding technique or materials that is the cause.

- Clustered porosity - is a localized grouping of pores that results from improper initiation or termination of the welding arc.

- Linear porosity - is porosity aligned along a joint boundary, the root of the weld, or an inter-bead boundary.

Causes:

- Damp flux / corroded electrodes (MMA)

- Presence of grease, hydrocarbon, water on prepared surface

- Air entrapment in gas shield (MIG/MAG, TIG)

- Incorrect deoxidant in electrode, filler or parent metal

- Too high arc voltage or length

- Gas evolution from primer

- Too high shielding gas flow rate causing turbulence (MIG/MAG, TIG)

Worm hole

A form of pores, which is most prevalent, apart from spheres, is a type known as worm hole porosity. This pore is roughly elliptical in shape and has its major axis normal to the advancing solidification wave. Where irregular shaped voids are present or where cavities occur in groups, these are perhaps due to mechanically entrapped gas caused by arc instability. Worm holes in fillet welds extends from the root of the weld toward the surface of the weld. Most of the worm holes found in welds do not extend to the surface.

Causes:

- Gross contamination of prepared surface

- Laminated work surface

- Crevices in work surface due to joint geometry

Surface porosity

A gas pore that breaks the surface of the weld.

The types of cavities that are formed by shrinkage during solidification are:

- Interdentrite shrinkage

- Crater pipe

- Microshrinkage

Crater pipe

A shrinkage cavity at the end of the weld run. The main cause is the shrinkage during solidification.

Solid Inclusions

Solid foreign substances entrapped in the weld metal is called solid inclusion. These can be the following types:

- Slag inclusion

- Flux inclusion

- Oxide inclusion

- Metallic inclusion

Depending on the type, the first three may also be of the following:

- Linear

- Isolated

- Clustered

Slag Inclusions

It is caused by non-metallic solid material or slag trapped during welding. The imperfection is irregular shape and is found either in the weld metal or between weld metal and the base metal. In general, slag inclusions result from faulty welding techniques and failure of the designer to provide proper access for welding within the joint.

Elongated cavities usually parallel to the axis of the weld, which contain slag or other foreign matter are called Slag lines.

Flux Inclusions

It is caused by flux trapped during welding. The imperfection is of an irregular shape and thus differs in appearance from gas port.

Oxide Inclusions

It is caused by oxides trapped during welding.

Metal Inclusions

There can be three different types depending on the kind of metal - Tungsten, Copper or Other metal.

1. Tungsten Inclusion

Particles of tungsten can become embedded during TIG welding. This imperfection appears as a light area on radiographs due to the fact that tungsten is denser than the surrounding metal and absorbs more X-ray/gamma radiation.

Lack of Fusion and Penetration

Lack of Fusion

Lack of fusion is the result of improper welding techniques, improper penetration materials for welding or improper joint design. Deficiencies causing incomplete fusion include insufficient welding heat or lack of access to all boundaries of the weld joint that are to be fused during welding, or both.

1. Lack of sidewall fusion

2. Lack of inter-run fusion

3. Lack of root fusion

Lack of Penetration

1. Incomplete Penetration

2. Incomplete Root Penetration

Imperfect shape and dimensions

Undercut

Lack Of Fusion Additive Manufacturing

A gas cavity of essentially spherical shape trapped within the weld metal. It can be of various forms:

- Isolated

- Uniformly scattered porosity - is porosity uniformly distributed throughout a single pass weld or through several passes of multiple pass weld. It is usually faulty welding technique or materials that is the cause.

- Clustered porosity - is a localized grouping of pores that results from improper initiation or termination of the welding arc.

- Linear porosity - is porosity aligned along a joint boundary, the root of the weld, or an inter-bead boundary.

Causes:

- Damp flux / corroded electrodes (MMA)

- Presence of grease, hydrocarbon, water on prepared surface

- Air entrapment in gas shield (MIG/MAG, TIG)

- Incorrect deoxidant in electrode, filler or parent metal

- Too high arc voltage or length

- Gas evolution from primer

- Too high shielding gas flow rate causing turbulence (MIG/MAG, TIG)

Worm hole

A form of pores, which is most prevalent, apart from spheres, is a type known as worm hole porosity. This pore is roughly elliptical in shape and has its major axis normal to the advancing solidification wave. Where irregular shaped voids are present or where cavities occur in groups, these are perhaps due to mechanically entrapped gas caused by arc instability. Worm holes in fillet welds extends from the root of the weld toward the surface of the weld. Most of the worm holes found in welds do not extend to the surface.

Causes:

- Gross contamination of prepared surface

- Laminated work surface

- Crevices in work surface due to joint geometry

Surface porosity

A gas pore that breaks the surface of the weld.

The types of cavities that are formed by shrinkage during solidification are:

- Interdentrite shrinkage

- Crater pipe

- Microshrinkage

Crater pipe

A shrinkage cavity at the end of the weld run. The main cause is the shrinkage during solidification.

Solid Inclusions

Solid foreign substances entrapped in the weld metal is called solid inclusion. These can be the following types:

- Slag inclusion

- Flux inclusion

- Oxide inclusion

- Metallic inclusion

Depending on the type, the first three may also be of the following:

- Linear

- Isolated

- Clustered

Slag Inclusions

It is caused by non-metallic solid material or slag trapped during welding. The imperfection is irregular shape and is found either in the weld metal or between weld metal and the base metal. In general, slag inclusions result from faulty welding techniques and failure of the designer to provide proper access for welding within the joint.

Elongated cavities usually parallel to the axis of the weld, which contain slag or other foreign matter are called Slag lines.

Flux Inclusions

It is caused by flux trapped during welding. The imperfection is of an irregular shape and thus differs in appearance from gas port.

Oxide Inclusions

It is caused by oxides trapped during welding.

Metal Inclusions

There can be three different types depending on the kind of metal - Tungsten, Copper or Other metal.

1. Tungsten Inclusion

Particles of tungsten can become embedded during TIG welding. This imperfection appears as a light area on radiographs due to the fact that tungsten is denser than the surrounding metal and absorbs more X-ray/gamma radiation.

Lack of Fusion and Penetration

Lack of Fusion

Lack of fusion is the result of improper welding techniques, improper penetration materials for welding or improper joint design. Deficiencies causing incomplete fusion include insufficient welding heat or lack of access to all boundaries of the weld joint that are to be fused during welding, or both.

1. Lack of sidewall fusion

2. Lack of inter-run fusion

3. Lack of root fusion

Lack of Penetration

1. Incomplete Penetration

2. Incomplete Root Penetration

Imperfect shape and dimensions

Undercut

Lack Of Fusion Additive Manufacturing

Undercut is generally associated with either improper welding techniques or excessive welding currents, or both. It is generally located at the junction of weld and base metal (at the toe or root). Undercut discontinuities create a mechanical notch at the weld fusion boundary.

Excess Weld Metal

Excess Penetration

Overlap

Misalignment

Incompletely filled groove

Lack Of Fusion Examples

Irregular Width

Root Concavity

Burn-through

Lack Of Fusion Weld

Miscellaneous imperfections

Stray Arc

Local damage to the surface of the parent metal adjacent to the weld resulting from arcing or striking the arc outside the weld groove. This results in random areas of fused metal where the electrode, holder, or current return clamp have accidentally ouched the work.

Some of the causes of this are:

- Poor access to the work piece

- Missing insulation on electrode holder or torch

Spatter

Lack Of Fusion Weld Defect

Torn Surface

Grinding Damage

Chipping Damage

Under Flushing

References

Images Of Lack Of Fusion

- American Welding Society - Welding Inspection Guide

- CSWIP - Welding Inspection Guide